How Our Water Hydraulic Platform Elevators Work

Advanced Elevators’ water hydraulic platform lifts are a unique blend of mechanical simplicity and engineering precision. Designed and manufactured in New Zealand, our systems are the only water hydraulic elevators fully compliant with NZS4334:2012, both structurally and electronically.

System Architecture

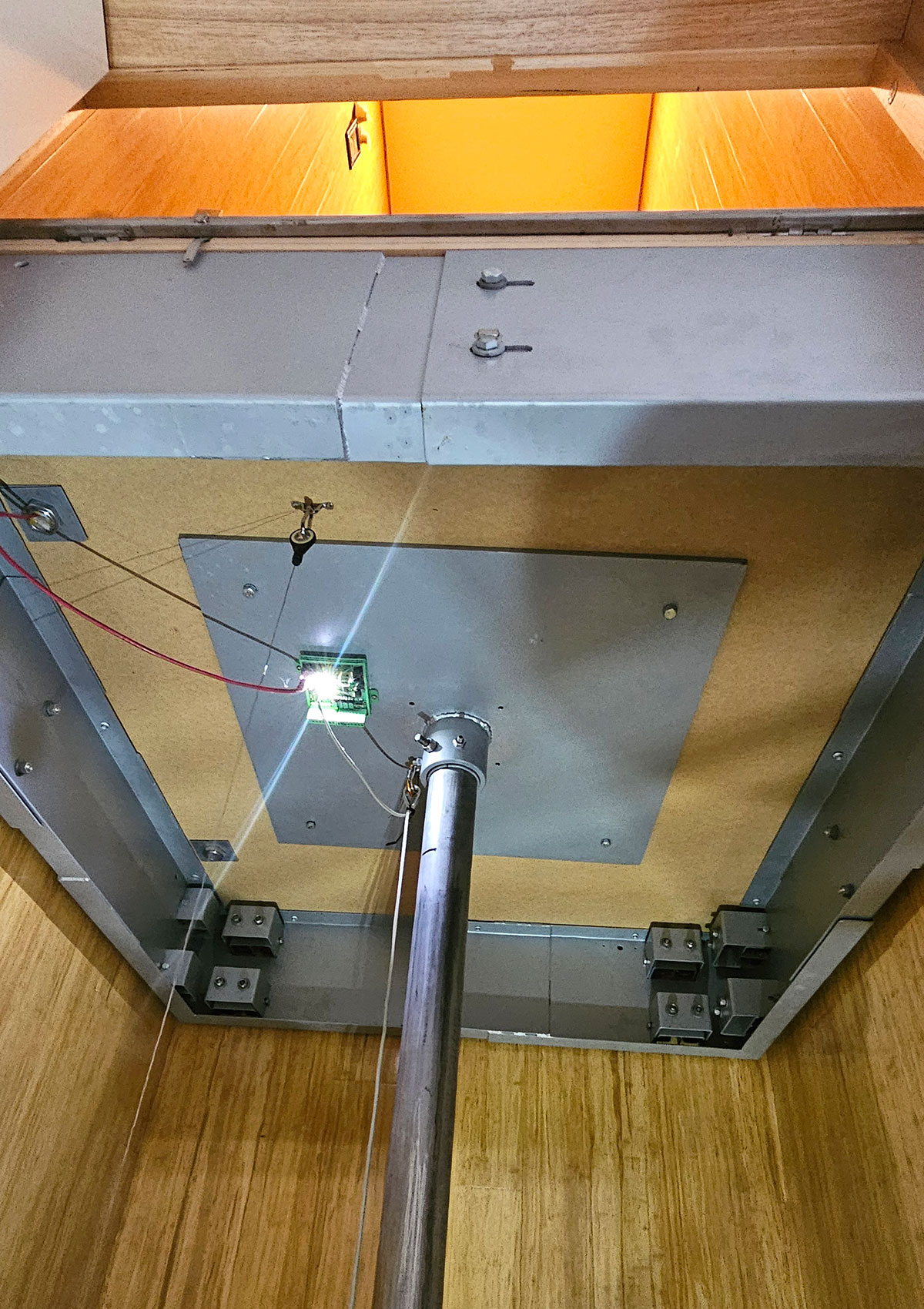

Our elevators are rail-guided platform lifts powered by a direct-acting water hydraulic ram. The system consists of:

A robust aluminium-framed shaft with precision-aligned guide rails ensures smooth vertical travel and structural integrity.

The platform is supported by a stainless steel hydraulic ram, reinforced brackets, and corner roller assemblies for stability and quiet operation.

Housed in a dedicated plant room, this unit includes:

- A 60+L polyethylene water reservoir

- An Italian stainless steel submersible pump

- Solenoid valves for controlled lift movement provide speed control during ascent and descent

- Manual lowering and isolation valves for safety and maintenance.

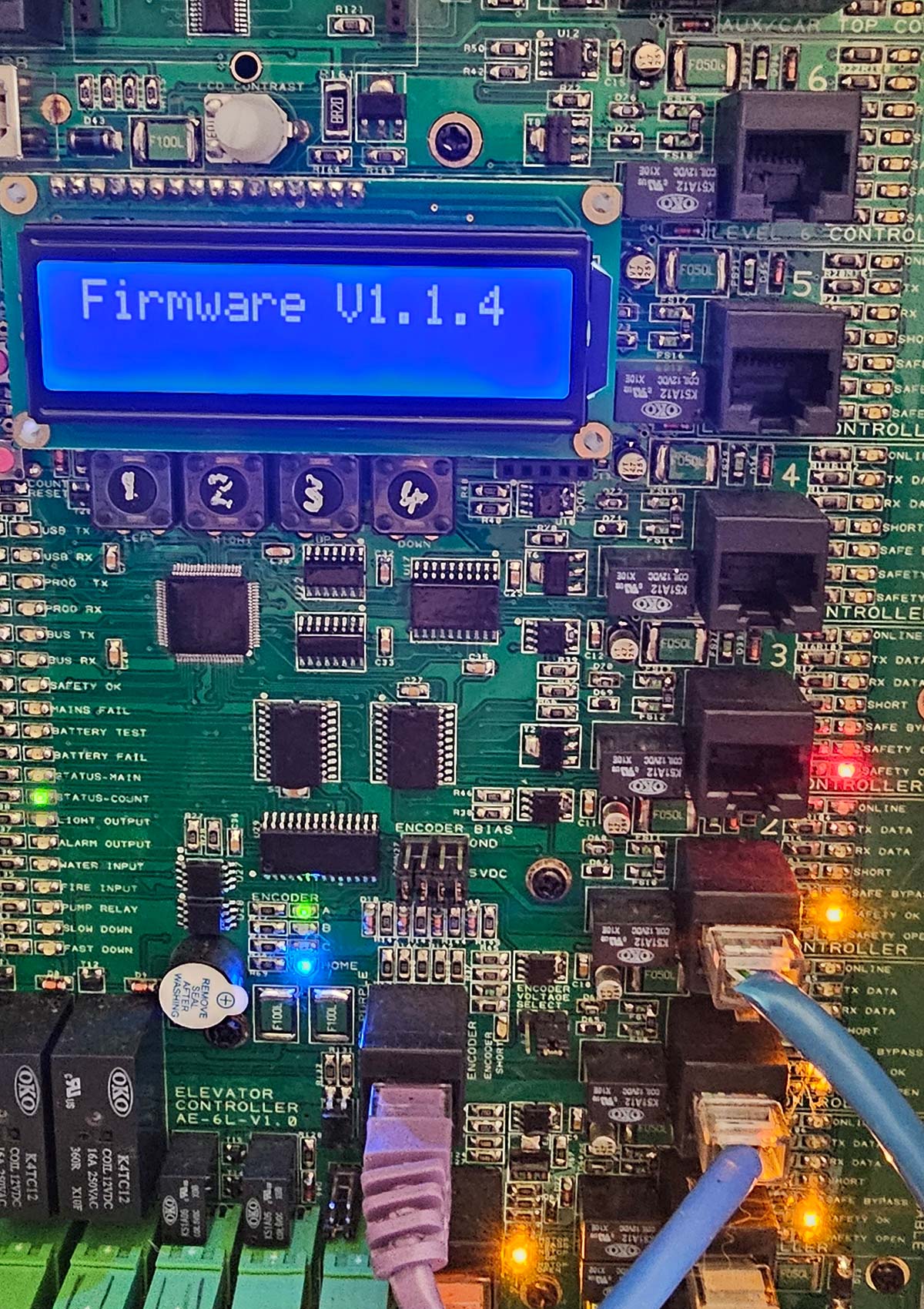

A microprocessor-based intelligent controller manages lift operations, safety interlocks, and user interface. It includes:

- Battery-backed 12VDC control power

- LCD display for diagnostics

- Emergency lighting and pit moisture alarms.

Operating Principle

When a user calls the lift, the pump activates and pressurizes water from the reservoir into the hydraulic ram, the valves provide a soft start to the ascent. This extends the ram, raising the platform smoothly along the guide rails until the destination level is reached and the valves reduce the speed to slow the platform to a stop at the right level

To descend, two solenoid valves open in a controlled sequence to release water from the ram back into the reservoir. The platform lowers under controlled pressure, with adjustable descent speeds via ball valves.

- Trip Rails: 10mm perimeter rails prevent movement if obstructed.

- Wire rope encoder: these high quality encoders provide level information to the controller in real time wo the controller always knows where the platform is in the shaft

- Dual Door Sensors: provide redundancy and ensure all landing doors are closed and locked before movement.

- Manual Override: In case of power failure, the lift can be manually lowered using the valve manifold.

- Ram Construction: The hydraulic ram includes an integrated flow restriction within the feed pipe, which regulates water movement during both ascent and descent. This built-in safety feature ensures that, even in the event of a feed hose failure, the platform will descend at a controlled rate and will not overspeed.

Compliance & Certification

Our systems are certified by:

- Coulter Engineering Services Ltd (Structural)

- Vertrans Lift Surveys & Certification Ltd (Electronic)

They meet or exceed:

- NZS4334:2012

- NZ Building Code D2

Technical Specifications

- Max Travel: 6.25m @ 1200×1200

- Platform Size: 1400×1400 @ 5m

- Safe Working Load: 340kg

- Pit Depth: 500mm

- Power Supply: 230VAC / 10A

- Water Supply: 15mm Wingback

- Overflow Drain: 40mm Waste Pipe